Paving News & Insights

Is Seal Coating Worth the Price?

Clients are often curious about the benefits of seal coating. First, let’s cover what it does for your asphalt pavement.

Seal coating is a protective layer added to the surface, protecting it from UV rays,as well as surface wear and tear. It also fills in surface damage that may occur.

Our next question from clients is often, “Is it really worth the price?”

The short answer is yes, but the long answer may surprise you.

Request a Seal Coating Proposal

The Cost of Seal Coating

Replacement of an asphalt parking lot is an expensive proposition these days. With oil prices at a five-year high, coupled with a disturbing labor shortage, installing asphalt has become like putting new granite tile in your entryway!

Truth: a nice granite tile job is about $6-20 a square foot. Asphalt patching is running $4-$7 per square foot, and a mill and overlay replacement can run anywhere from $2.50 to $3.50 a square foot.

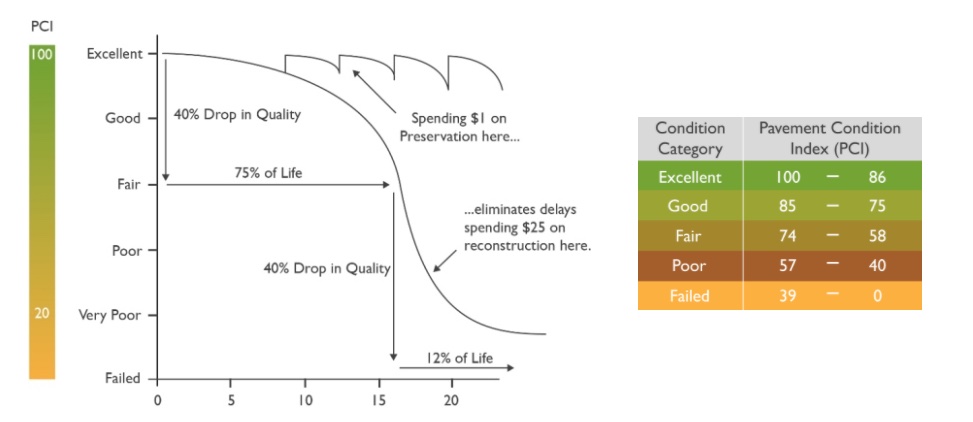

On the other hand, a seal coat and crack fill will run between 15-30 cents per square foot and will greatly extend the parking lot’s life. So, keeping that parking lot healthy should start to look pretty good.

“A well-paved and maintained asphalt parking lot should last about 20 years. Anything that we contractors can on do to slow the rate of deterioration improves the life cycle of your parking lot and protects your long-term investment.”

Chuck Jeffries, Owner of Kansas Asphalt

Benefits of Seal Coating

Seal coating and crack filling have multiple benefits including:

- reducing oxidation from the sun

- improving the curb appeal of the parking lot

- preventing erosion of the surface

- maintaining the value

- preventing water from entering the asphalt through hairline cracks

Preventing Water Damage

Now let’s dig into why water damage can be such a problem with asphalt surfaces and why seal coating can make such a difference.

Water that penetrates asphalt can lead to deeper cracks and failure of the subgrade, which is the compacted material underneath the asphalt. When the subgrade fails and becomes soft, the weight of traffic on the asphalt pushes it downward creating cracks and ruts. Asphalt also becomes brittle over time as the oil leaves the mix making it more susceptible to cracking. Seal coating slows that process. Once the asphalt has degraded to a certain level, the damage cannot be resolved with any topical product and removal is the only option.

Keep in mind, though, that nothing can completely prevent water from entering asphalt or prevent oxidation from occurring.

“The most efficient and cost-effective way to preserve any asphalt parking area is to use a regular pavement maintenance plan.”

Chuck Jeffries, Owner

The Importance of a Pavement Maintenance Plan

A good pavement maintenance plan should include:

- aggressive repair of potholes or damage

- proper use of crack filling before cracks become too wide to repair

- annual or semiannual seal coating

The frequency of seal coating depends on the climate, wear and tear, and the sealer that is used. Generally, tar-based products tend to last a year longer than asphalt-based sealers. The choice of sealer is dictated most often by contractor preference and availability.

Regardless of the product you choose, scheduled maintenance with a good seal coating product will add years of life to your valuable asset.

Have questions about seal coating for your surface? Don’t hesitate to reach out to our Kansas Asphalt team.